Listen to 2009 World Barista Champion جويليم دافيز narrate this lesson

Listen to 2009 World Barista Champion جويليم دافيز narrate this lesson

Grinding is the process of applying stress to a material to break it up into smaller particles. Two types of stress are applied during grinding: الضغط, in which the material is pressed against a surface, and shear, in which force from two different directions is applied to different parts of the material.

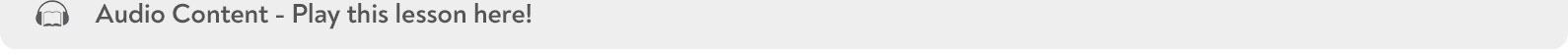

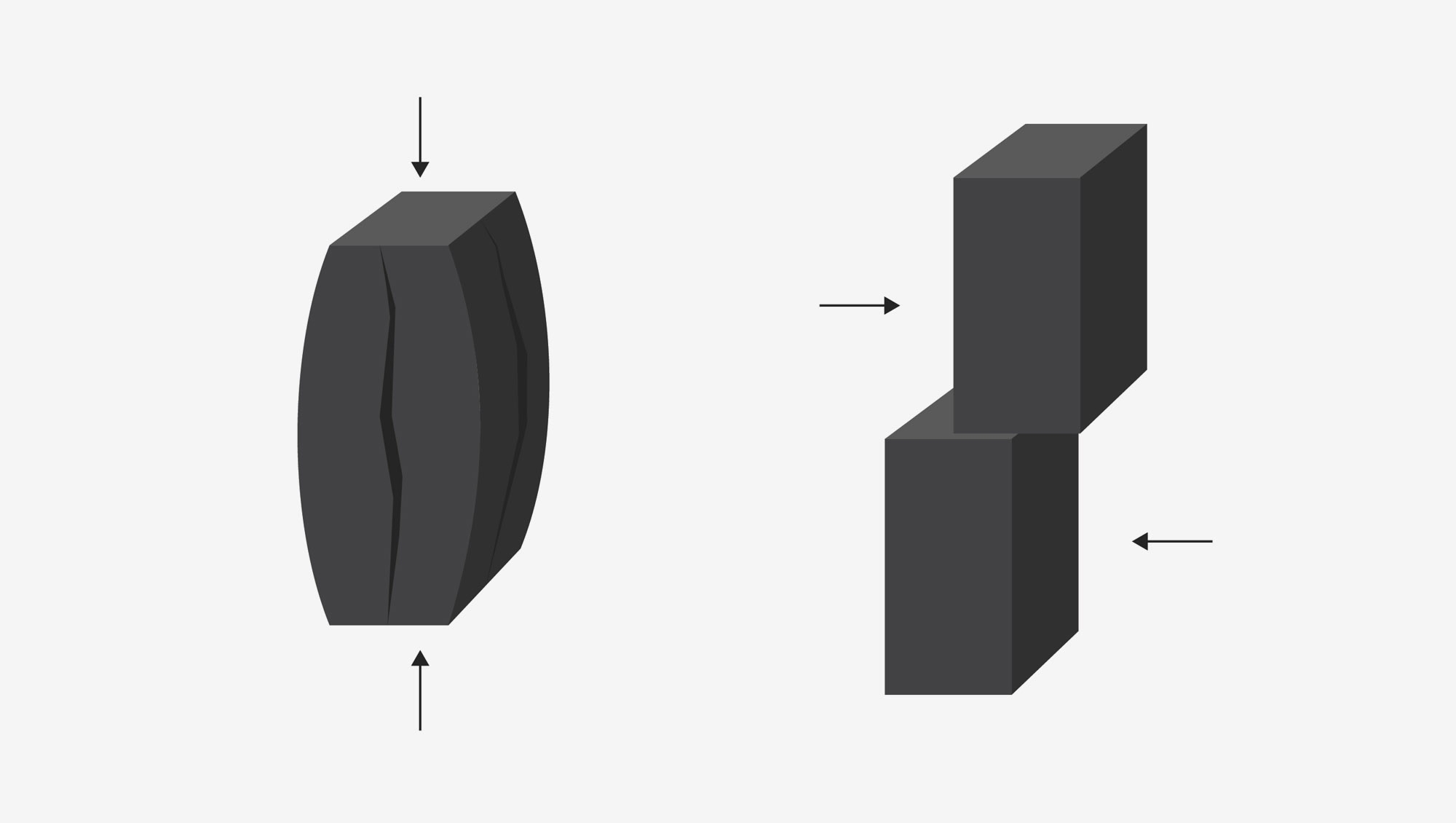

Image: Compression (left) and shear (right)

Image: Compression (left) and shear (right)

Under الضغط stress, fractures are created anywhere the material has a weakness, until the fractures join together to burst the material into a number of randomly sized and shaped particles. Shear stress, on the other hand, generally creates fractures along the plane of shear, as shown in the diagram, leading to a more uniform particle size and shape and more even extraction.

The most effective grinders use both kinds of stress: الضغط in the first stage, called ‘pre-breaking’, to crush the beans and produce pieces roughly 1 millimetre in size, followed by shear stresses in the second stage, called ‘grinding’ or ‘finishing’, where the sharp burr edges move against each other to ‘cut’ the broken pieces into particles of a more uniform size. (M Petracco, 2005)

The cutting-type action of this second stage is essential to produce ground coffee with particles of suitable size and shape for brewing (RJ Clarke, 1987). Impact grinding, such as takes place in blade grinders, uses only الضغط forces and so cannot produce a defined particle size or shape. This is also one reason that sharp التروس are so important: as التروس become blunter, the particles are subjected to more الضغط and less shear, producing more random particle sizes and shapes.

Commercial espresso grinders use either flat or conical التروس, and the coffee is passed through a small gap between rotating teeth that cut the coffee fragments into the desired particle size. Conical التروس are popular in espresso grinders,