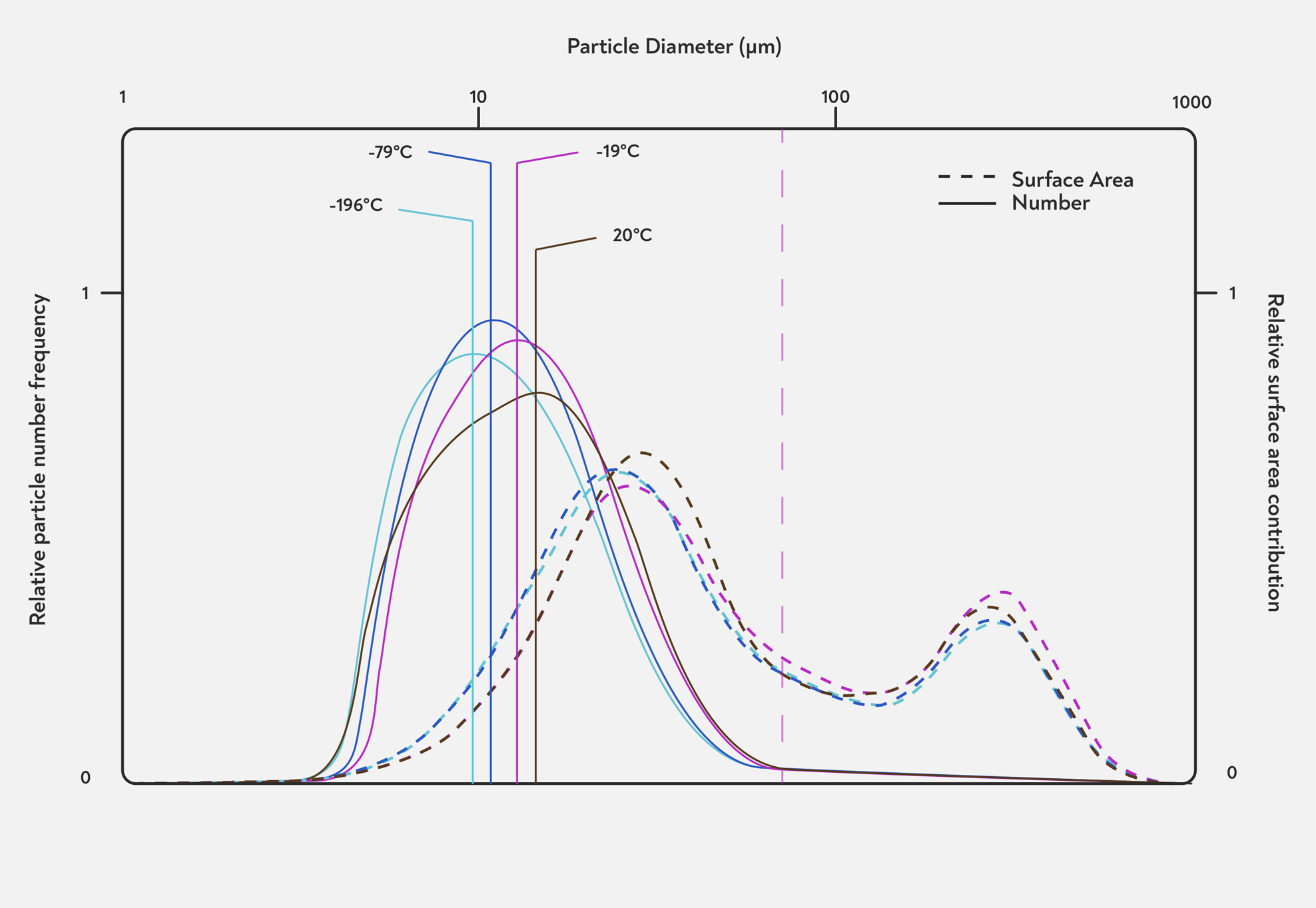

The temperature in the grinder has a noticeable effect on توزيع حجم الطحن. We’ve all experienced this firsthand when shots begin to run faster during busy periods. Setting the grinder to a finer setting can compensate for the change in shot time, but the shots don’t taste the same as those produced from a cold grinder at a coarser setting.

What’s happening is that the توزيع حجم الطحن, rather than the overall grind size, is changing. While there is very limited published research on this, the available evidence suggests that the grinding coffee in a warmer grinder reduces the surface area contribution from الطحن الناعم, which in turn could reduce extraction and negatively affect the flavour.

As the coffee gets warmer, it becomes more plastic and less هشًا, which means that each time a particle is cut or crushed, it breaks into fewer pieces and creates fewer الطحن الناعم. It also means that some larger particles are able to escape from between the التروس more easily (E Uman et al., 2016).

Conversely, cooling coffee beans prior to grinding can decrease the range of particle sizes and produce very tasty espresso. In their 2017 paper ‘The effect of bean origin and temperature on grinding roasted coffee’, Barista Hustle founder Matthew Perger collaborated with a group of scientists and coffee professionals to explore the effect of temperature on توزيع حجم الطحن (E Uman et al., 2016).

They found that cooling the beans before grinding had a distinct effect on the توزيع حجم الطحن, producing a larger number of الطحن الناعم. The الطحن الناعم produced are more uniform in size, as can be seen by the taller peaks at around 10 μm in the graph below, for temperatures below -19° C (-2.2° F). Because the الطحن الناعم are the main contributors to extraction in espresso, more evenly sized الطحن الناعم means the extraction will be more even, overall.

This complex chart from E. Uman et al., 2016 is explained in detail in the video below