When a modern lever machine sits idle, a narrow band of hot water is allowed to syphon around the outside of the piston in order to keep the group heads hot. For this reason, the components of the plunger are usually made of brass because of its excellent thermal conductivity. (We will elaborate on thermosyphons in the following chapter.) Rather than using the thermo syphon system, Gaggia’s Classica model relied on the steam pressure in the boiler to push the water up to the group head. Nonetheless, the old system and the modern system both use hot water to keep the groups hot.

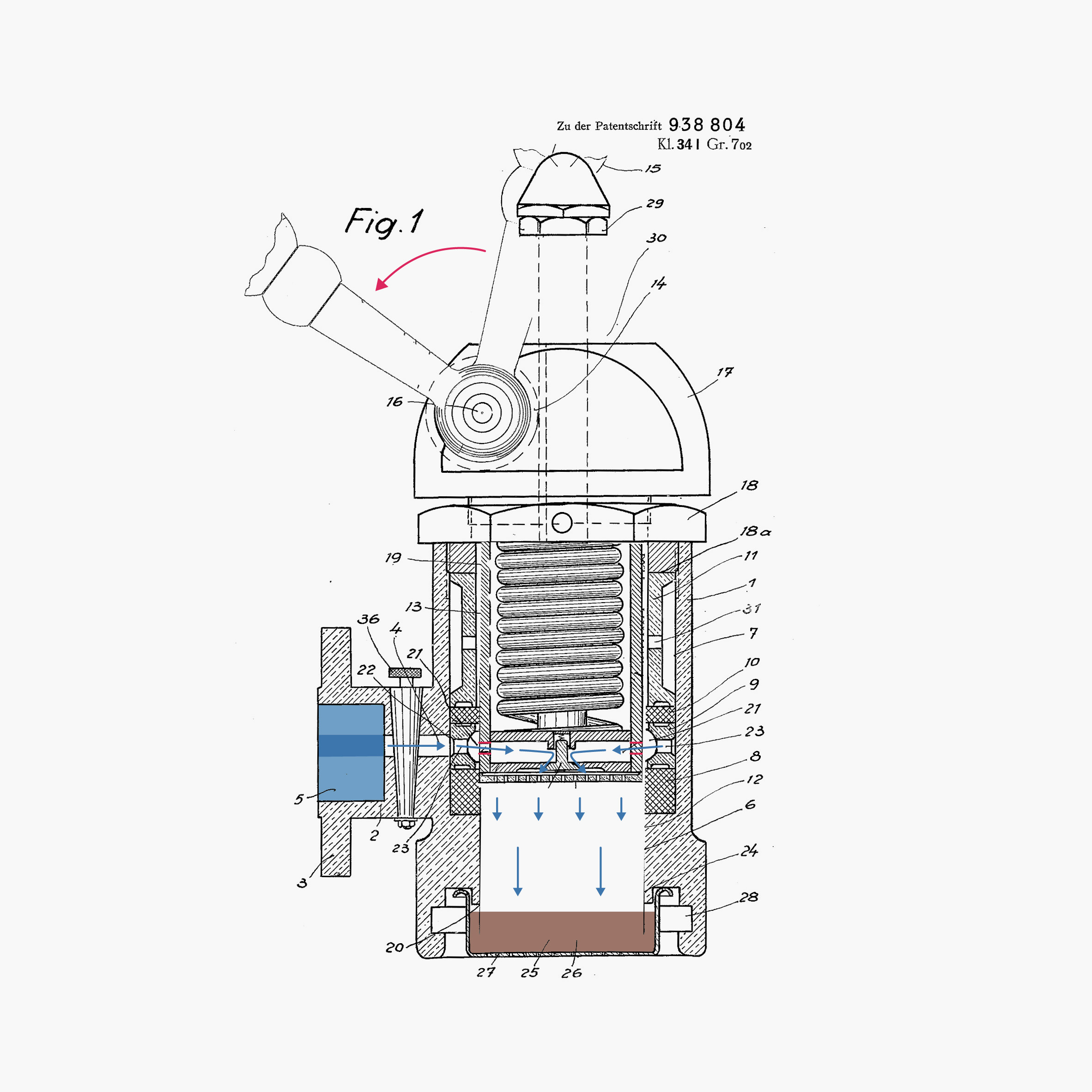

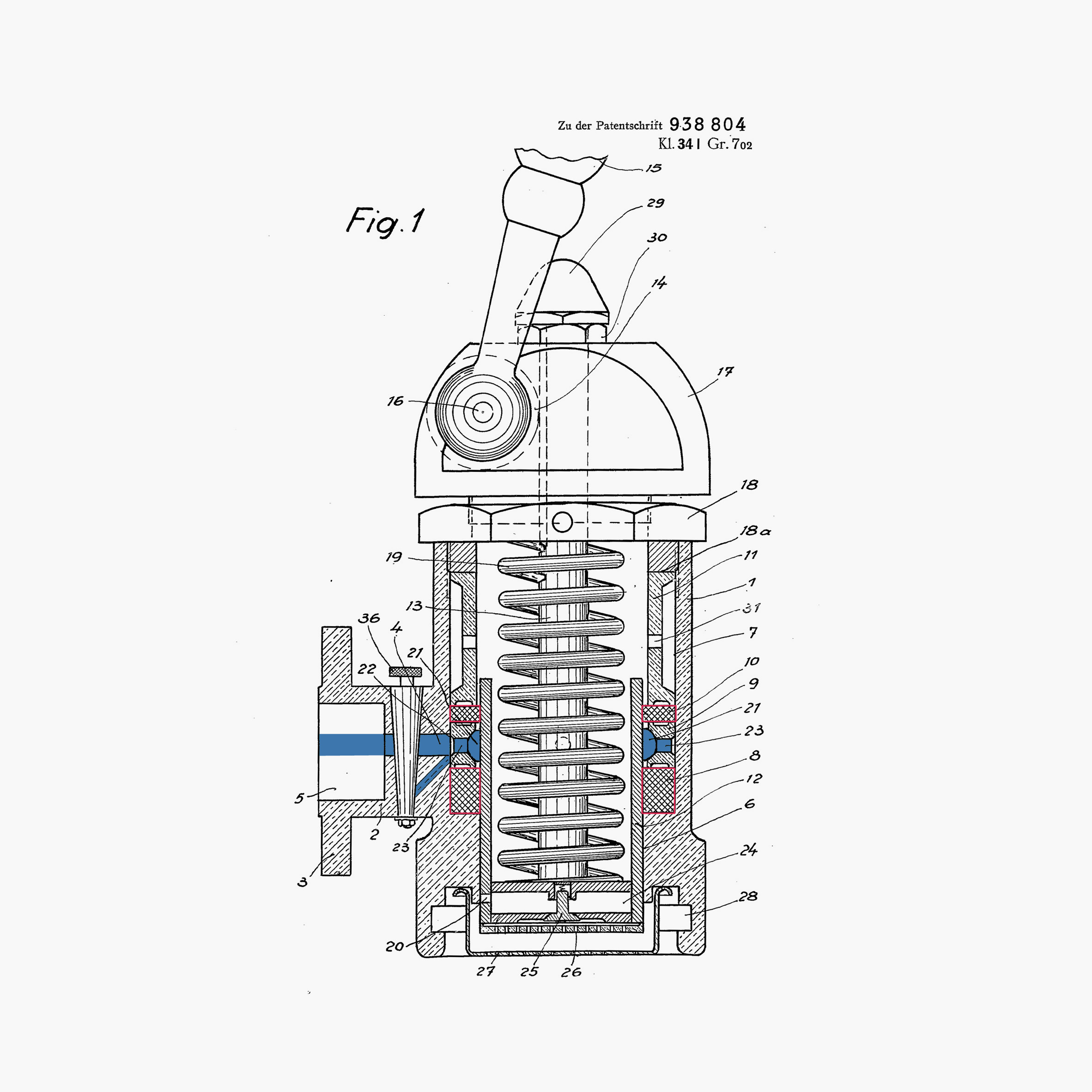

The blue colour shows the narrow band of water surrounding the brass plunger. The red squares and the large o-rings designed to make a water tight seal sound the outside of the piston.

The blue colour shows the narrow band of water surrounding the brass plunger. The red squares and the large o-rings designed to make a water tight seal sound the outside of the piston.

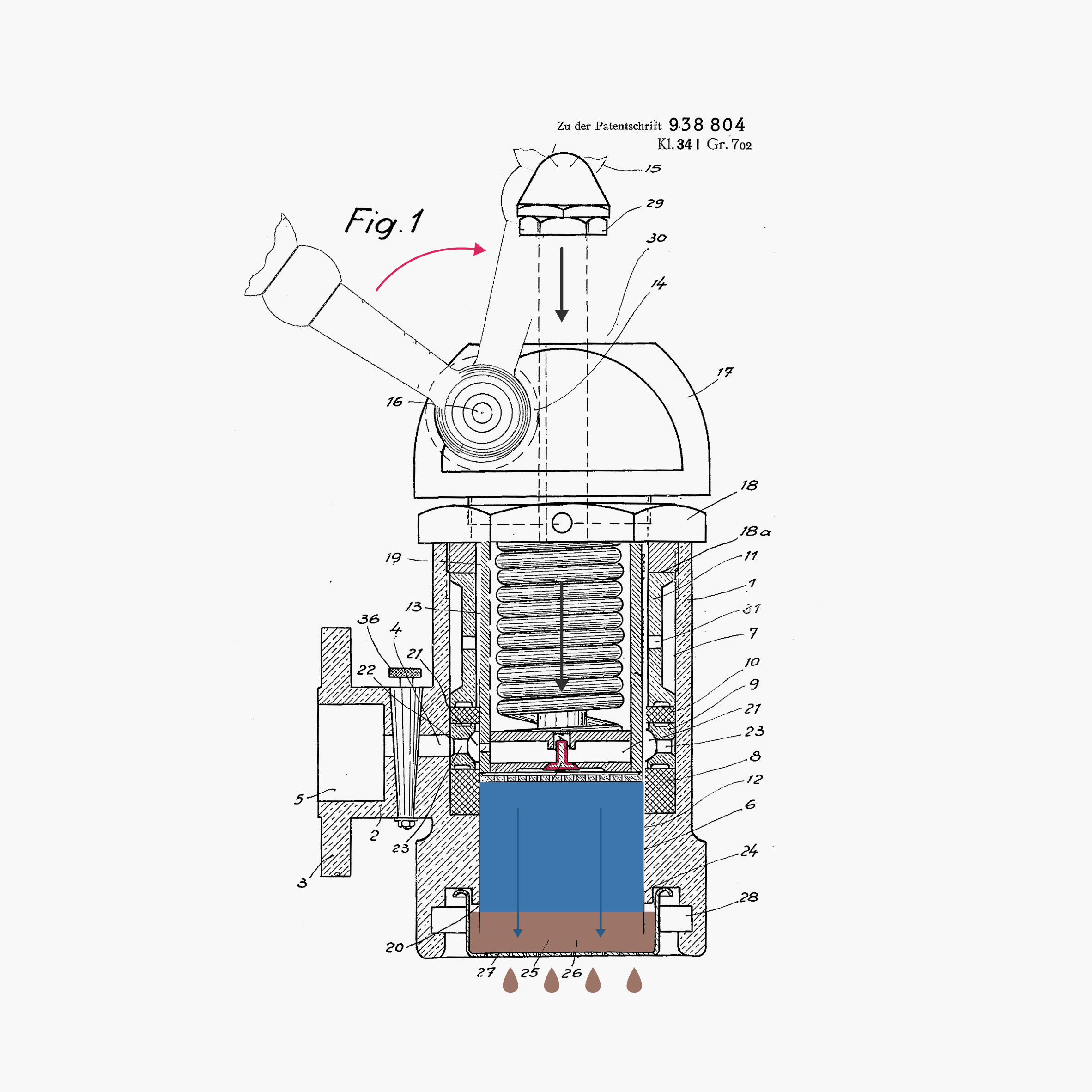

On Gaggia’s machine, when the barista pulls the lever, the plunger moves upwards a distance of around 50 millimetres. The plunger slides up to a position inline with the band of water surrounding the grouphead and the holes in the sleeve allow water to pour onto the coffee.

No pressure builds up inside the group until the chamber above the coffee bed is entirely saturated with water, with no space for air between the plunger and the top of the coffee bed. It takes about 5 seconds for the chamber above the puck to fill with water and another 5 seconds for the puck to become fully saturated. That means Gaggia’s lever machine performed a 10-second preinfusion. (You can learn more about the benefits of preinfusion here, in Barista Hustle’s Advanced Espresso course.)

Note: An important health and safety warning. It’s extremely important to have a firm grip on the lever when operating any kind of lever machine. If the lever slips out of your hand it can catapult back into the upright position and cause injury.

Note: An important health and safety warning. It’s extremely important to have a firm grip on the lever when operating any kind of lever machine. If the lever slips out of your hand it can catapult back into the upright position and cause injury.

Gaggia’s system was able to reach pressures in excess of 11 bars of pressure.