The Effect of Steam Pressure on Bubble Size

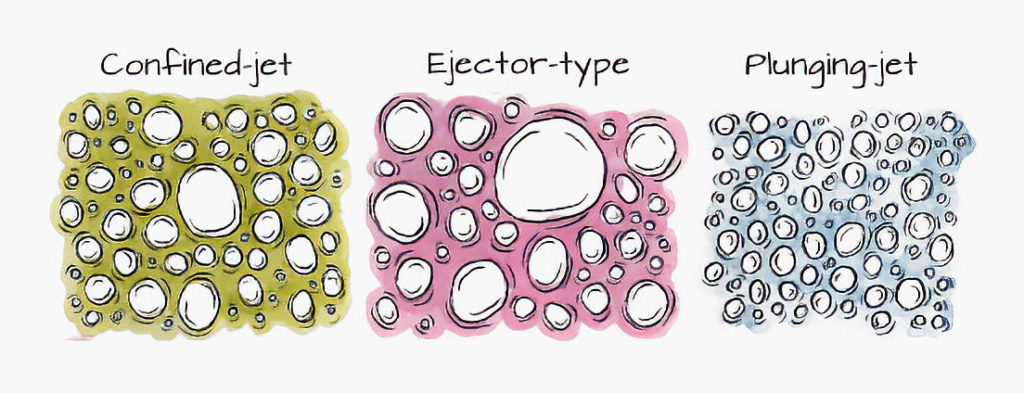

Are you looking for an efficient milk heating solution by increasing your steam temperature? Turning up the temperature of the steam boiler comes at the expense of milk foam quality. Regardless of steam wand type, bubbles get bigger when the espresso machine operates at higher pressures. Researchers have observed that for every 0.2-bar increase in boiler pressure, the average bubble diameter increased by 3 um (Jimenez-Junca et al 2015).

This research showed that of all the commercial systems for heating milk, the foam from the plunging jet steam wand system (i.e., a normal steam wand) was the least affected by increases in pressure. Ejector-type steam wands, used on bean-to-cup machines, recorded a bubble diameter increase of 10 um per 0.2 bar increase in pressure. These ejector-type systems feature an air pump running alongside a steam injector.

One surprising finding from the research indicated that the most successful combination of small bubbles and firmness of foam corresponded with a much higher pressure than is considered safe for use in a modern espresso machine: ‘In general, foams produced between steam pressures of 180 and 280 kPa [kilopascal; one bar equals 100 kPa] with the plunging-jet nozzle had the desired combination of low bubble size, high foam stability and stiffness…’. These findings suggest we are far from the end game for steam wand development on modern espresso machines.

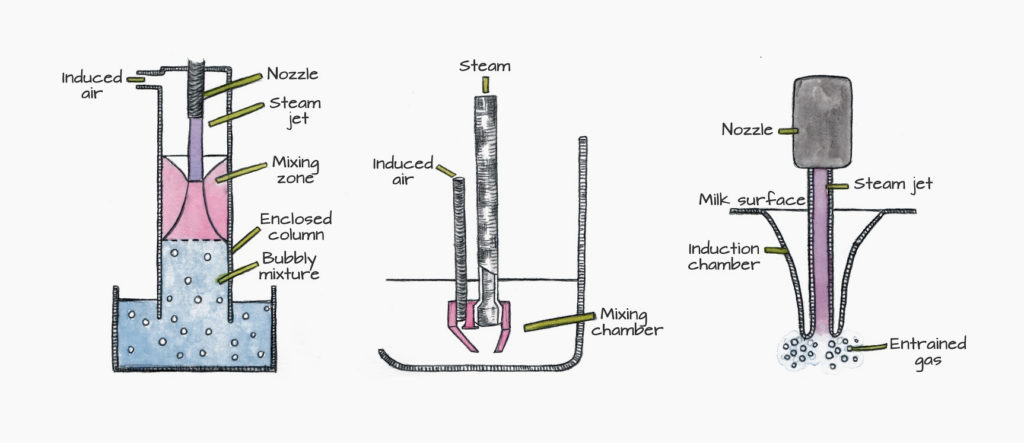

In the sketches below, we recapture fig 1 and fig 6 from Jimenez-Junca et al 2015 which depict three steam wand types and their resultant foam qualities. The corresponding foam is positioned beneath each wand dip.

Maintenance

Steam wands require regular maintenance. Over time, all steam wands are likely to calcify, so you need to remove and descale them periodically. Through a process known as syphoning, spent milk can find its way up inside the steam wand. The pipes that draw the steam from the boiler to the steam wand are fitted with a check valve (a non-return valve) which is designed to prevent any liquid milk from penetrating the system upstream of this valve.