The most common issue you will encounter with catering equipment, with regard to reduced functioning, is limescale. Water that contains dissolved calcium and magnesium salts (usually acquired as rainwater percolates through bedrock and becomes groundwater) is prone to releasing some of these minerals when it is heated. Water that has been in contact with the open air also contains dissolved carbon dioxide (CO2). The dissolved calcium and the CO2 bond in water and form the compound calcium bicarbonate. This stuff won’t form limescale (‘scale’, for short) until it changes its chemical structure and releases the CO2. When we heat up water for brewing, we release the CO2 and cause a compound known as calcium carbonate to form. This stuff then falls out of the water (precipitates) and attaches to the elements and the surfaces of the boiler, coating them in the exact same material limestone is made of.

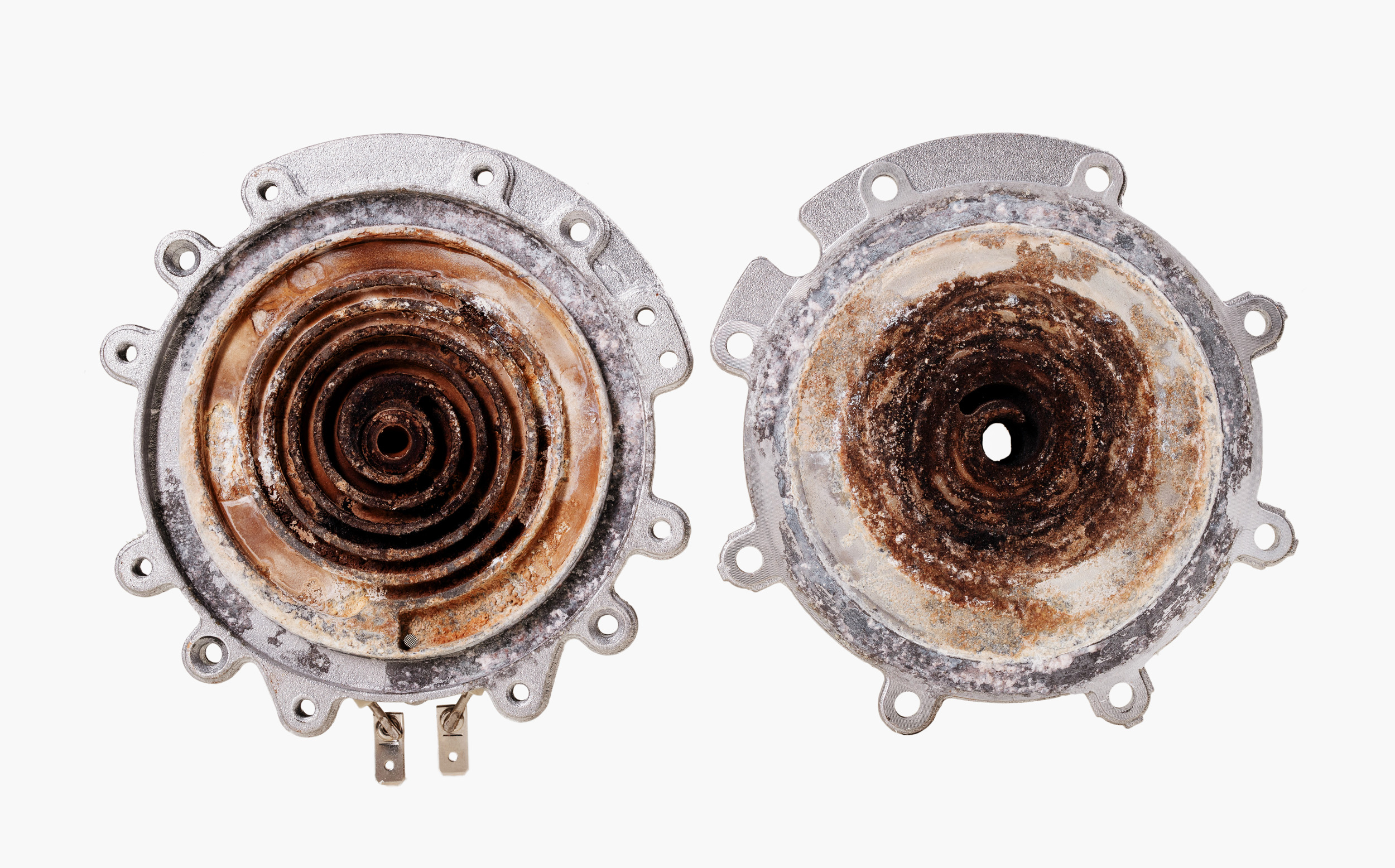

Scale formation on the internal parts of a boiler element.

Scale formation on the internal parts of a boiler element.

Fortunately, because brewers don’t usually operate with as much flow restriction, brewing machines tends to be more resistant than espresso machines to limescale buildup. The flow restriction in brewing machines doesn’t require water to travel through tiny, 0.5-millimetre flow restrictors, the way most modern espresso machines do. The heating elements and sprayheads of mechanical brewers are prone to a buildup of scale, however. The heating elements on large brewing machines usually take the form of a twist of thick copper or a plate of aluminium. Limescale, which is not as thermally conductive as copper or aluminium, has the effect of encasing heating elements in an insulating layer.

To keep your energy bill from being needlessly high and to avoid the possibility of the machine developing leaks around the seals, it is important to periodically determine whether your equipment needs to be descaled. Descaling should be carried out by a qualified person who can inspect the boiler to determine whether the scale has reached a level that requires removal. A slight buildup of scale can provide a beneficial protection to the surfaces of your elements and boiler walls.