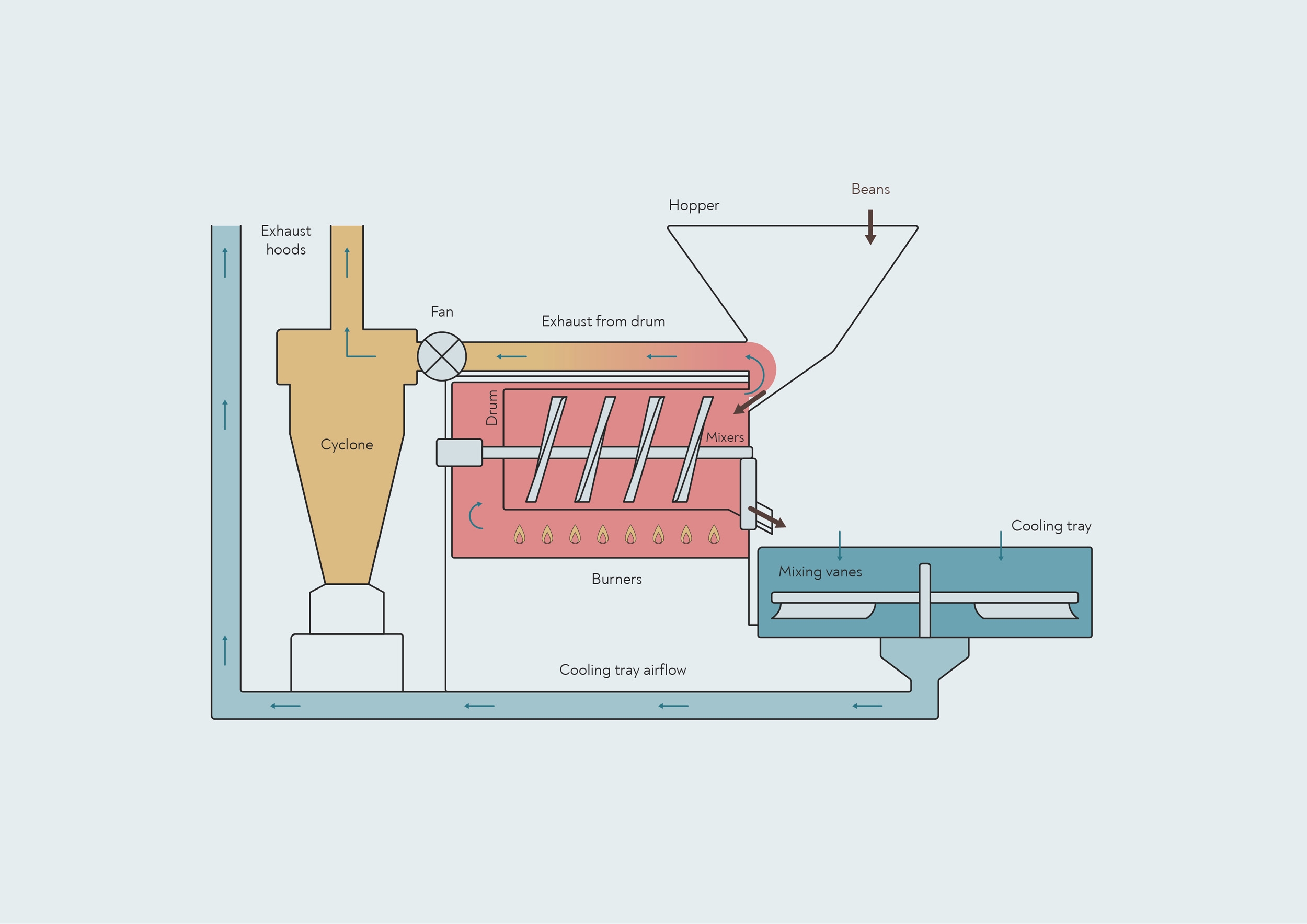

Modern directly heated drum roasters share the same basic features. The diagram below shows the features of a typical directly heated drum roaster.

Schematic of a directly heated drum roaster. Brown arrows show the movement of beans through the roaster; white arrows show airflow. Adapted from Pereira et al 2020

Schematic of a directly heated drum roaster. Brown arrows show the movement of beans through the roaster; white arrows show airflow. Adapted from Pereira et al 2020

A gas burner (or other heat source) underneath the drum heats the drum wall directly. At the same time, a fan in the exhaust draws air into the roasting machine. The burners rapidly heat the air when it enters the machine, and that hot air then passes through the drum until it reaches the exhaust.

Beans enter the drum via a hopper positioned above the roasting machine. Mixing vanes within the drum stir the beans as it rotates, to ensure even heating. The beans are heated mainly by conduction from the drum walls and convection from the hot air passing through the drum. The exhaust fan draws roasting fumes and chaff out of the drum during the roast, and a cyclone separates chaff from the exhaust gases.

At the end of the roast, the beans pass through a door at the front of the drum and drop into the cooling tray. A powerful fan draws cold air over the beans while mixing vanes stir them to ensure rapid, even cooling.

The Drum

The interior of a drum roaster, showing the mixing vanes or flights

The interior of a drum roaster, showing the mixing vanes or flights

A drum can be either single- or double-walled and made of either solid or perforated metal. Directly heated drums are generally made of solid metal in order to protect beans from the heat of the flame. The exceptions are some designs in which the heating element is also designed to transmit some heat to the beans via infrared radiation.

A double-walled drum is made of two layers of metal with an air gap between them. This insulates the inner drum surface from the heat of the flame,