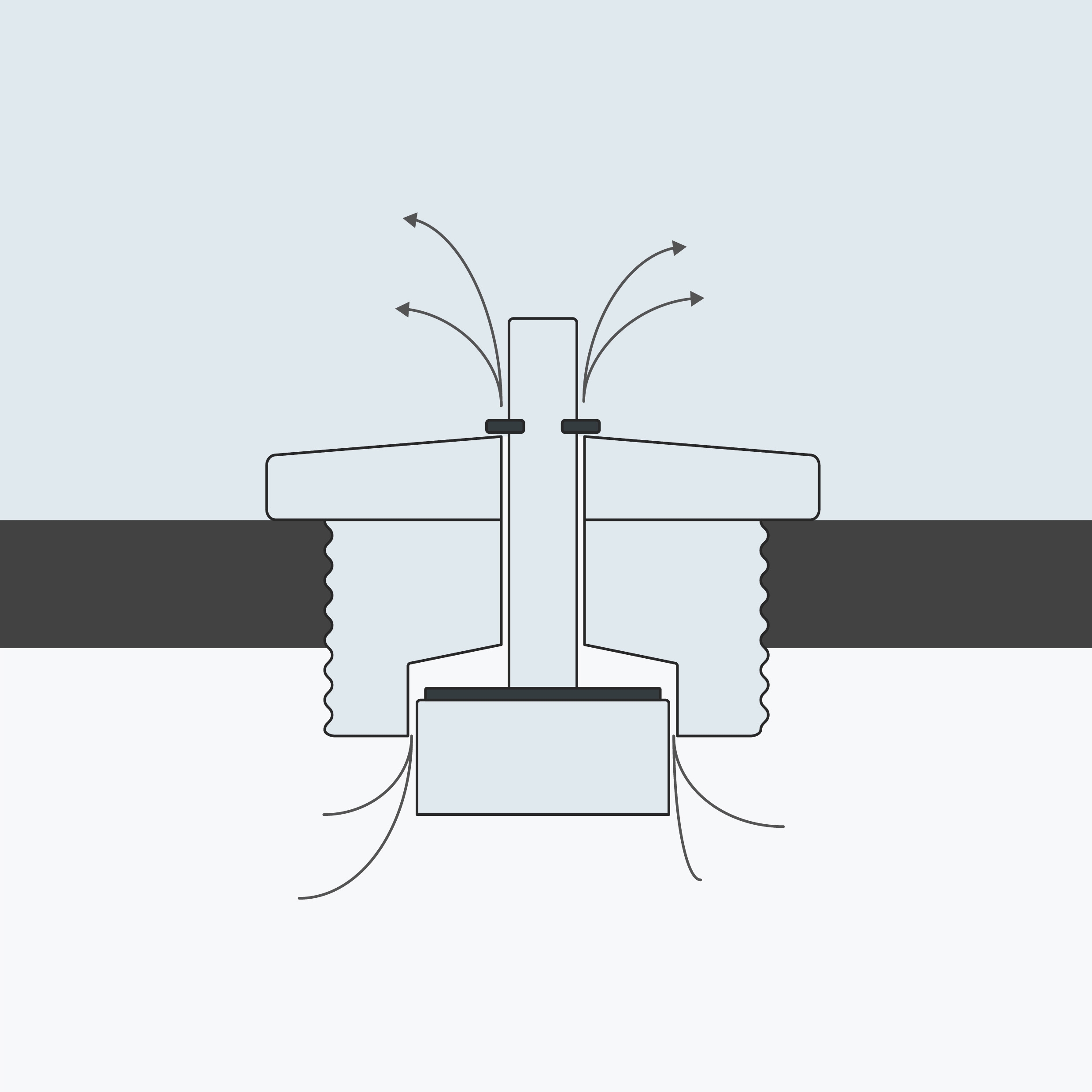

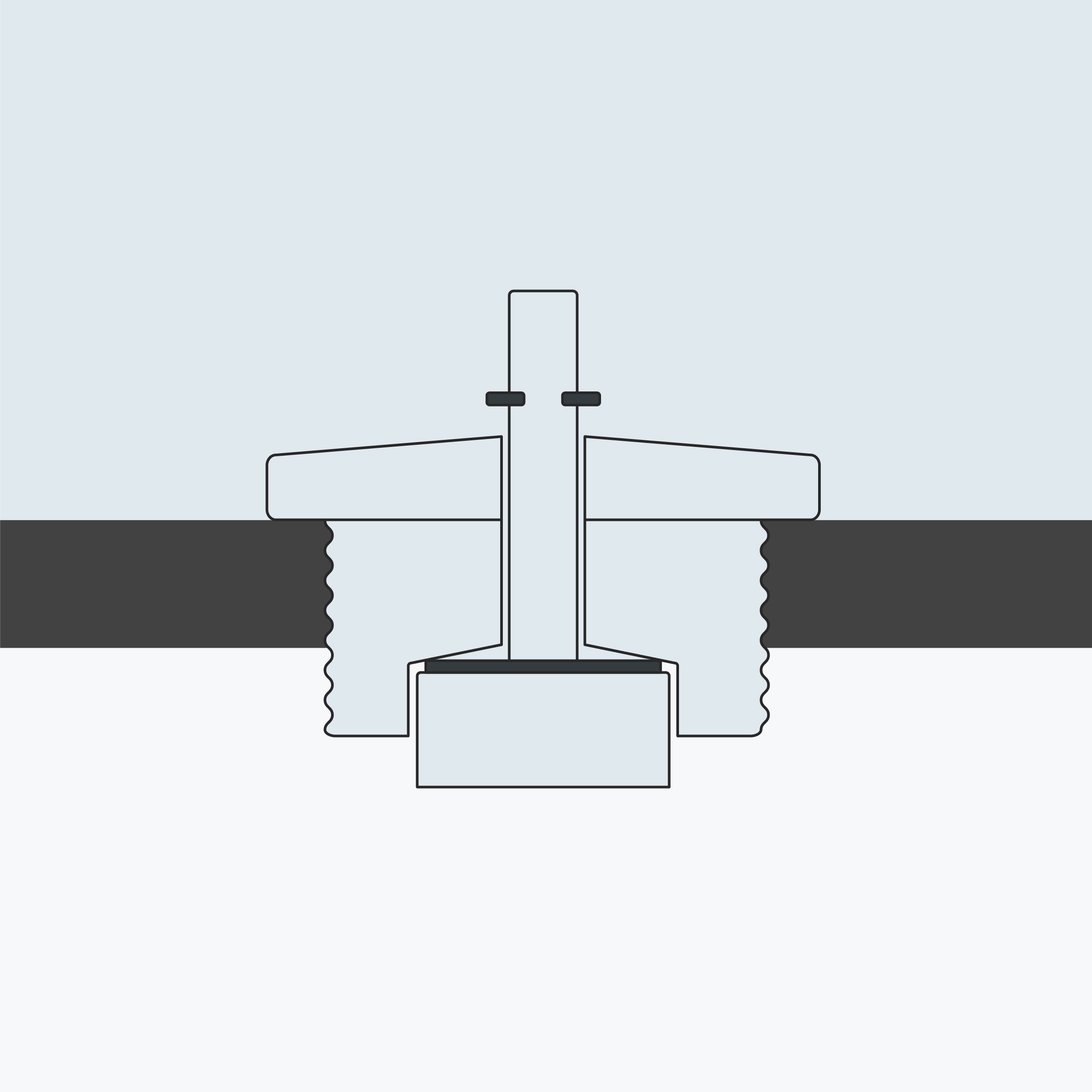

This diagram shows a cross section of an antivac valve. When there’s no pressure in the boiler, the valve seat will be in the open position (left image). When the boiler is powered, steam pressure forces the valve seat to close (right image). In this way, the antivac valve’s function is the reverse of the safety valve’s.

If you hear a little fizz أو hiss as your machine begins to heat up, don’t be concerned (though you should always keep an eye on your espresso machine’s pressure gauge).