The invention of the air roaster revolutionised coffee roasting, allowing faster roasts on larger scales than had ever been possible before. In the decades since it was invented, the air roaster became hugely important in industrial coffee roasting — although the classic drum roaster remains the machine of choice for most smaller-scale roasteries.

But who was responsible for introducing this radical idea? Like all inventions, the development of air roasting can’t be pinned down to a single moment of inspiration. In this post, we explore the most important milestones along the way — beginning, paradoxically, with the inventors responsible for the modern form of the drum roaster.

The Drum Roaster

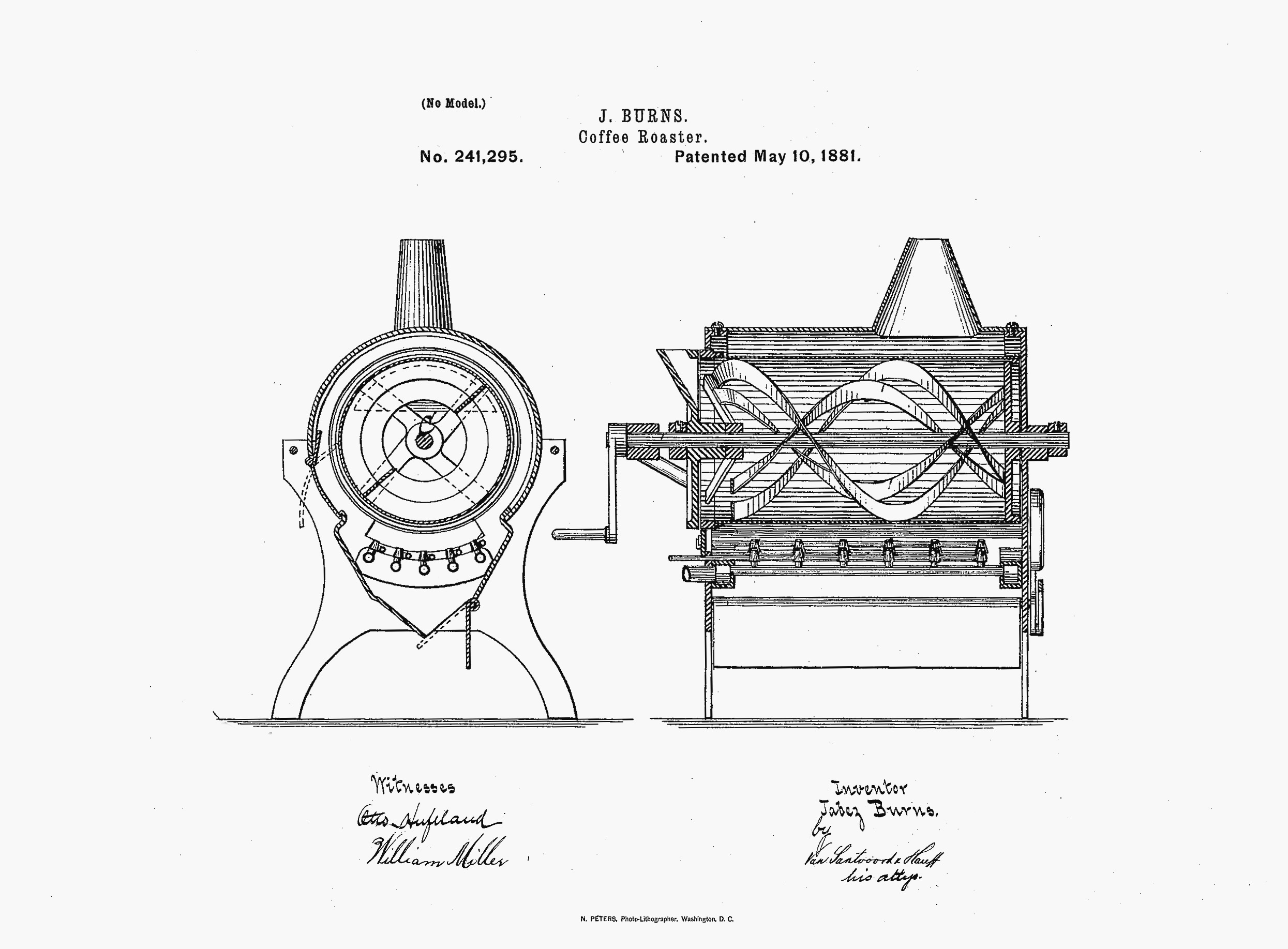

The basic design of the drum roaster as we know it today was established in the 1880s, and has barely changed since. Jabez Burns established many of the essential features of a drum roaster in his 1864 patent, and the vast majority of roasting machines in use today follow the same essential principles.

Jabez Burns’s coffee-roasting machine (detail from his 1881 patent)

Jabez Burns’s coffee-roasting machine (detail from his 1881 patent)

Since then, manufacturers have released a multitude of different designs for coffee roasters, each with their passionate advocates and detractors. We dedicated the first chapter of our Roasting Science course to analysing the strengths and weaknesses of the different designs on the market, and talking to prominent roasters about their experiences using different types of roasting machine.

The common feature in many ‘new’ roaster designs is that they use hot air to heat the beans, rather than heating the roasting drum directly. Despite some manufacturer’s predictions, air roasters have so far failed to completely displace the classic drum roaster — but there’s no doubt that the development of hot air roasting has also greatly influenced the design of modern drum roasters, and brought about a huge change in the way coffee is roasted. In fact, understanding the importance of hot air in coffee roasting is arguably the biggest advance in all of coffee roasting’s history.

The Importance of Hot Air

A couple of decades after Burns built his drum roaster, Alex van Gülpen improved on Burns’s design by introducing controlled airflow. van Gülpen’s design featured a fan, which drew air through the drum to remove roasting gases (Bersten 1993). van Gülpen was one of the founders of Emmericher Maschinenfabrik und Eisengießerei, the company that later became Probat.

It may have been the German inventor Carl Salomon, however, who was the first person to fully realise the full importance of controlling airflow in coffee roasting. He described this insight in a patent in 1892. Convection — via hot air — is much more efficient and transferring heat to beans than conduction from the drum walls. Salomon realised that using convection for heat transfer allows for much faster roasting, without the risk of burning the beans’ surface.

Until then, trying to roast coffee quickly in a conduction-based roaster risked scorching the beans on the hot surface of the drum. To avoid this, roasters would use low temperatures, with roasting times of up to an hour in commercial roasteries. “Slow roasting” might sound romantic, but kills the coffee’s acidity and aroma, resulting in some pretty unpleasant coffee. As Salomon put it in his patent:

‘In the methods hitherto in use for roasting coffee … high temperatures have been carefully avoided for fear of too-highly roasting or even burning the beans.… Owing to the long duration of those roasting processes the soluble extract has partly been decomposed or destroyed.”

By using hot air as the major heat source, Salomon reported, it is possible to roast at higher temperatures without risking burning the beans. This innovation meant that coffee could be roasted in less than ten minutes for the first time. He also noted an additional benefit of increasing airflow: it removes smoke and chaff from the drum, resulting in cleaner-tasting coffee.

Indirect Heat

Once the importance of hot air was established, the logical next step was to do away with direct heat on the drum entirely, and to heat the roaster only with hot air. Indirectly-heated drum roasters following this principle began to appear in the early twentieth century.

Indirectly heated drum roasters could fairly be considered the first air roasters, even if they looked superficially similar to the classic drum roasters — because they used hot air as the only heat source.

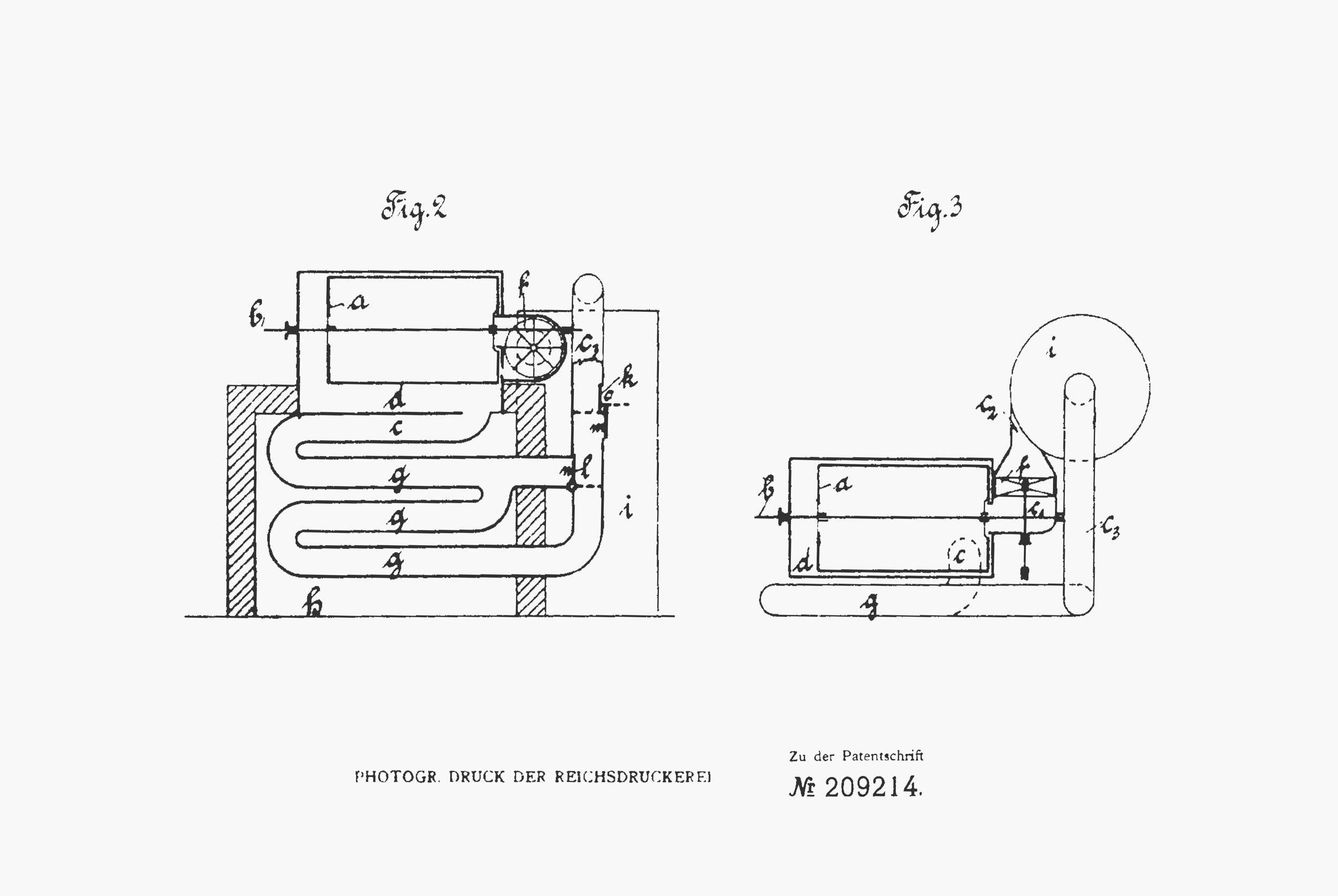

Theodor Vogeler’s 1908 design for an indirectly heated drum roaster uses a heat exchanger (g) to heat the air before it enters the drum (a).

Theodor Vogeler’s 1908 design for an indirectly heated drum roaster uses a heat exchanger (g) to heat the air before it enters the drum (a).

If indirect roasters are considered the first air roasters, though, we don’t know who should be credited with the invention. In his book All About Coffee, William Ukers (1922) credits the first indirectly heated roasting machine to Joseph Lambert — better known as the (possible) inventor of peanut butter (Smith 2007). The only published patents from Lambert’s company, however, describe roasting machines that feature a gas burner inside the drum. This may seem strange now, but was a common enough design at the time. The ‘indirect’ heating Ukers mentions probably refers to the heat shield Lambert used to protect the beans from the direct heat of the flame, rather than to a true indirectly-heated roaster.

The First Fluid Bed

A fluid bed uses airflow to fluidise the beans — lifting them up in the stream of air so that they float, and behave more like a liquid. The fluidised beans can move around freely in the stream of air, and thereby roast evenly without the need for moving paddles or a rotating drum.

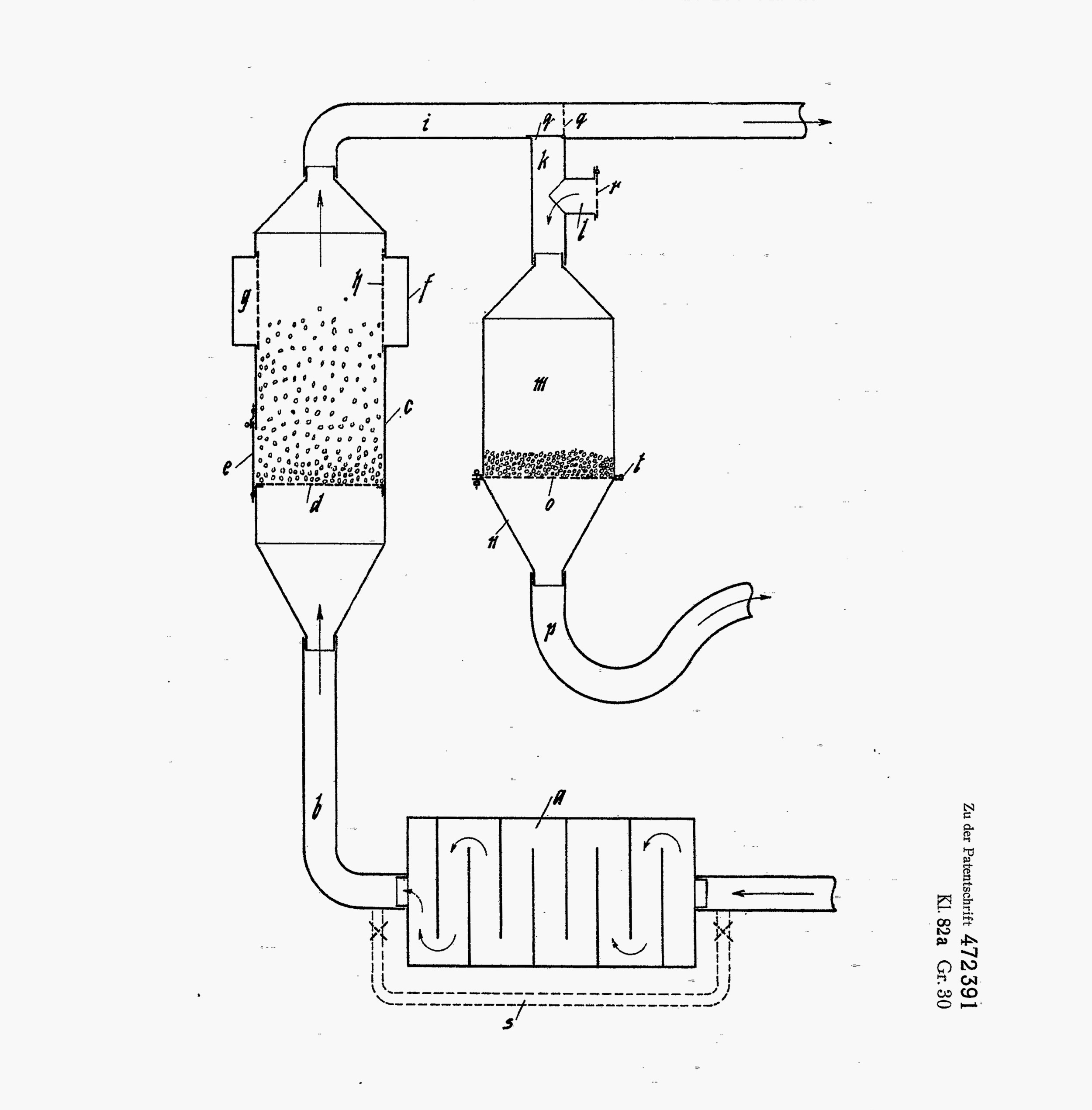

Once the concept of air roasting had been established at the beginning of the twentieth century, fluid-bed roasters followed surprisingly quickly. Fluid beds were first used in the chemical industry in 1922 and just four years later in 1926, Heinrich Caasen had already patented a design for a fluid-bed coffee roaster (Caasen 1929).

Heinrich Caasen’s 1926 design for a fluid-bed roaster. The beans are loaded onto a sieve (d) and then fluidised in hot air blown in from a heat exchanger (a). After roasting, a second fan sucks the beans into the chamber (m) for cooling.

Heinrich Caasen’s 1926 design for a fluid-bed roaster. The beans are loaded onto a sieve (d) and then fluidised in hot air blown in from a heat exchanger (a). After roasting, a second fan sucks the beans into the chamber (m) for cooling.

It took another 30 years for the fluid-bed roaster to be commercialised, however. Lurgi launched the Aerotherm in 1957, in collaboration with the coffee company Heimbs and the University of Braunschweig (ABZ 2005). The Aerotherm was discontinued at some point in the early 1970s (Sivetz and Desrosier 1979).

Michael Sivetz

Michael Sivetz was a legendary figure in coffee — a brilliant and sometimes irascible chemical engineer who came to apply his skills and analytical thinking to the coffee industry. Sivetz was born in 1922, the year that fluid-beds were first used in the chemical industry. Building on his years of experience in both the chemical industry and commercial coffee roasting, Sivetz built and patented his first fluid-bed roaster in 1974. Shortly afterwards, he began a collaboration with the German manufacturer Neuhaus Neotec to commercialise the design, but was frustrated by the slow progress and soon began to carve his own path. At first, Sivetz built his roasting machines in his garage; later, he moved the business into a former church.

Sivetz acknowledged the existence of previous designs such as the Aerotherm in his patent (Sivetz 1976). Nonetheless he claimed to have invented the first practical fluid-bed roaster, based on the improvements he proposed over existing designs — which he dismissed as ‘so-called fluid-bed roasters’ (Sivetz 2002).

The most important improvements in Sivetz’s roaster were that the airflow was positioned to one side so that the beans would circulate, rather than float in place, and that he used a thermocouple to accurately read the temperature of the beans. Neither of these were a new feature in coffee roasters, but when combined in Sivetz’s design they made for an effective roasting machine, versions of which are still being built today.

The Missing Link

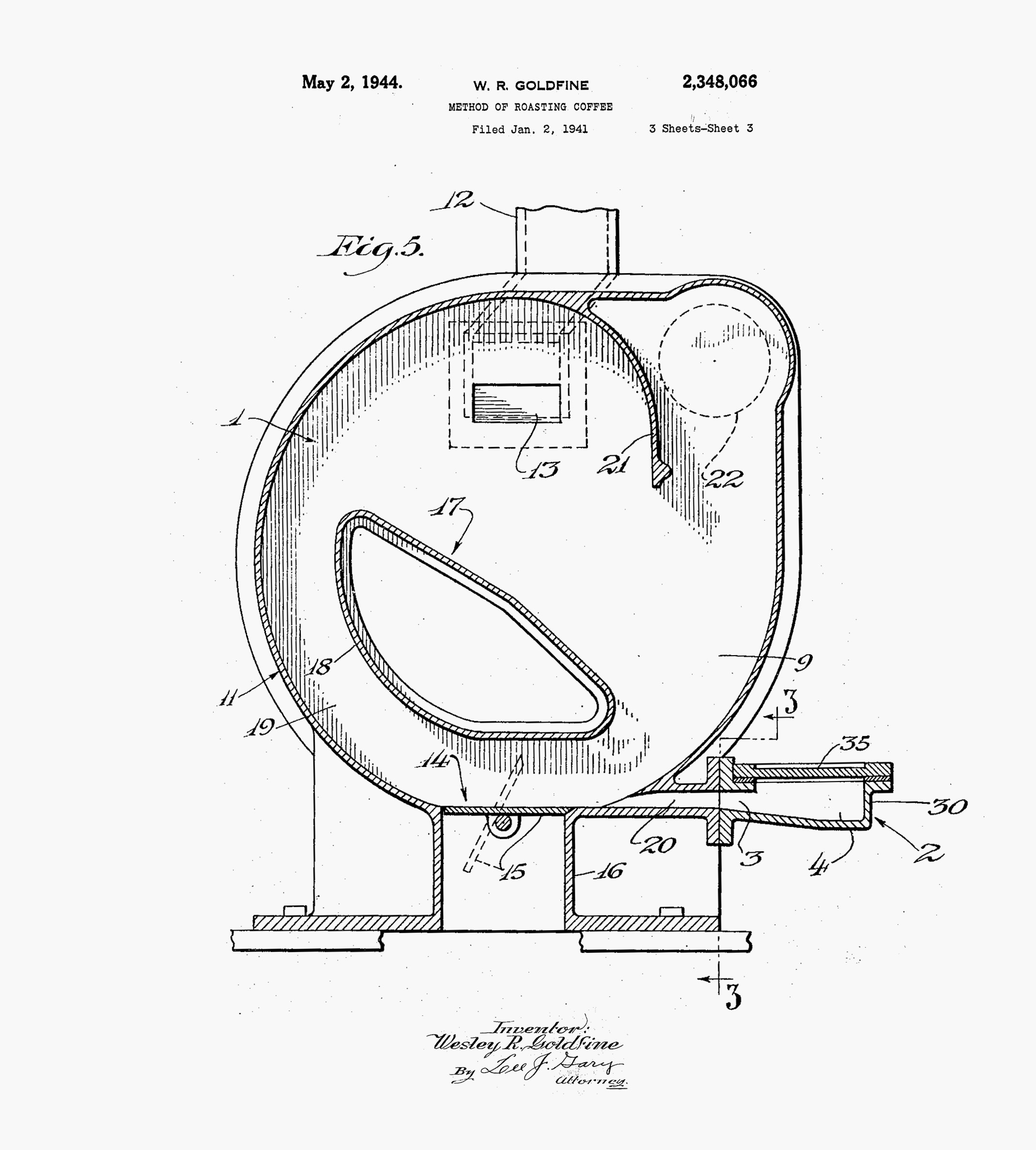

One often overlooked name in the story of the fluid-bed roaster is Wesley Goldfine. In his 1941 patent, Goldfine describes a machine that uses a jet of hot air coming in from one side of the bean pile, forcing the beans to circulate within the roaster.

Detail from Goldfine’s 1944 patent for an asymmetric spouted-bed roaster. Hot air injected into the base of the roaster caused beans to circulate in the cylindrical chamber

Detail from Goldfine’s 1944 patent for an asymmetric spouted-bed roaster. Hot air injected into the base of the roaster caused beans to circulate in the cylindrical chamber

While the original fluid-bed idea was borrowed from the chemical industry, Goldfine’s design was ahead of the curve: the first ‘spouted beds’ in the chemical industry, which operate on a similar principle, appeared a decade later (Mathur and Gishler 1955). The same principle drives the circulation of the beans in Sivetz’s roaster, as well as in many modern air roasters, including both large industrial machines and the Ikawa sample roasters.

A fluid-bed roaster with a 50 kg-capacity at Zarraffa’s Coffee in Queensland, Australia. Photo by Coffea, published under a Creative Commons licence

A fluid-bed roaster with a 50 kg-capacity at Zarraffa’s Coffee in Queensland, Australia. Photo by Coffea, published under a Creative Commons licence

Whether or not Sivetz could have fairly claimed to be the inventor of the first practical fluid-bed roaster is perhaps a matter of perspective. There’s no doubt though that, thanks to his knowledge and tenacity, he had a big impact on the coffee industry. Much like the question of who invented the espresso machine, the development of the air roaster is a story of continual, incremental progress, rather than a single ‘eureka’ moment that transformed the industry.

0 Comments