In this video, we take you to the beneficio at Finca La Senda, Guatemala where millers load the reception tank which gravity feeds into the drum pulper below. This gravity fed system does not require additional water to feed the cherries into the machine.

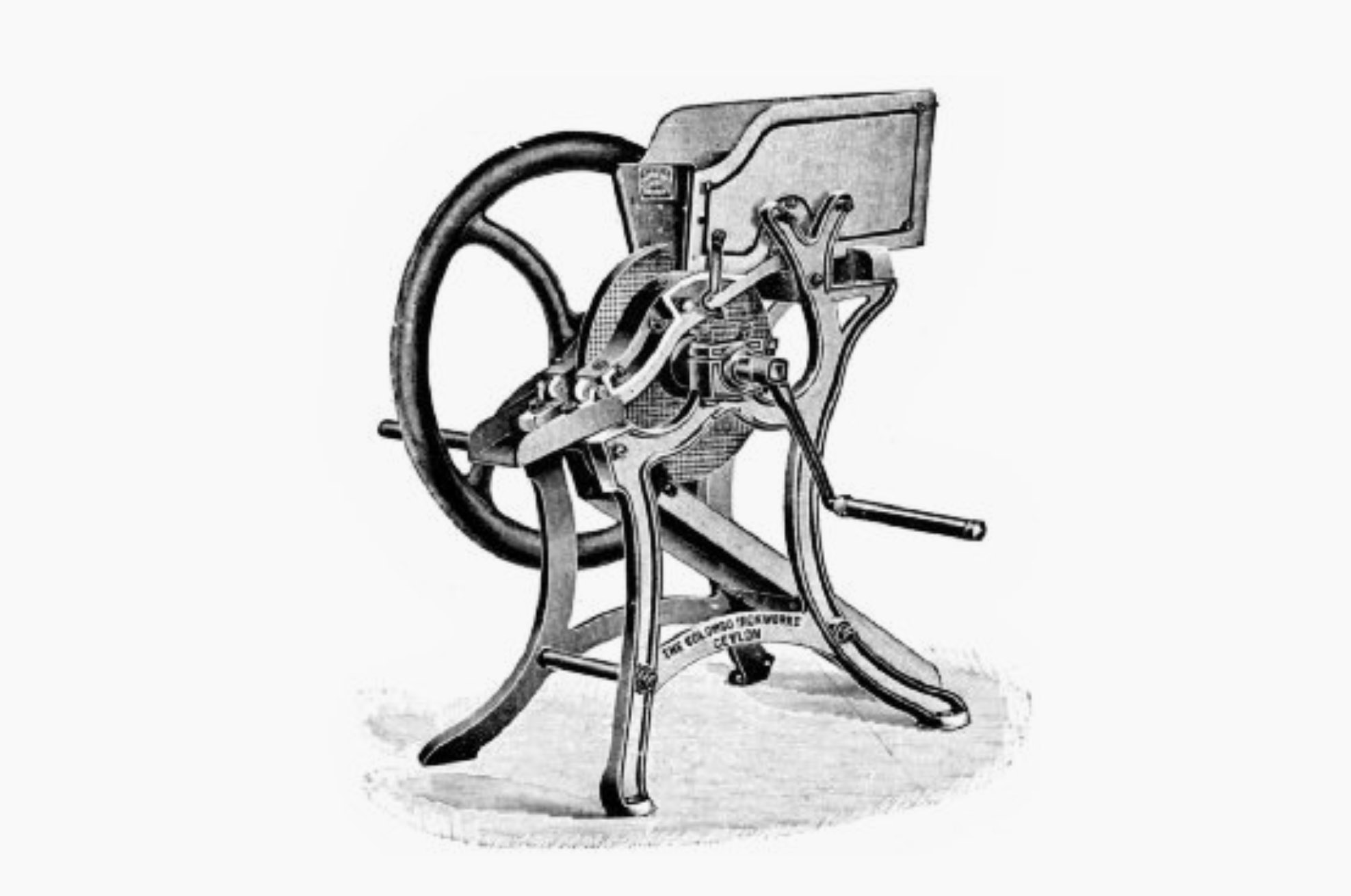

Walker’s original disk pulper patented in 1860.

Walker’s original disk pulper patented in 1860.

Pulping removes the exocarp and the outer mesocarp from the cherry. It’s a delicate operation because if the parchment layer is cut through and the beans are damaged, microbial attack can rapidly advance. Getting pulping right is a matter that underpins the financial and ecological health of coffee-growing regions that use the wet and pulped natural processes. Preventing blockages in the pulper whilst also avoiding the loss of too much parchment coffee as the pulp is removed are major issues for all processors, from small-scale farmers to huge factories.

Water is not strictly needed for a pulper to operate but it is widely used to help feed the cherry into the pulper. In a traditional wet mill, all the processing steps — from the reception tanks up until the coffee hits the fermentation tanks — consume 40 cubic metres of water per metric tonne of coffee (J. C. Vincent, 1987). Pulpers that use a lot of water and agitate the beans too violently can introduce a large amount of fibre into the water, which is very difficult to remove without sophisticated equipment. This makes recycling the water more difficult.

Farmers who selectively pick and then float their coffee have a much easier time when it comes to pulping. They don’t have to worry about damaging their equipment because the soft flesh of ripe cherry passes easily through any style of pulper. However, even the best pregrading cannot escape the fact that coffee cherry sizes vary from one harvest to the next. Every pulper needs to be correctly calibrated and serviced regularly to avoid losses.

Among the several pulping systems,