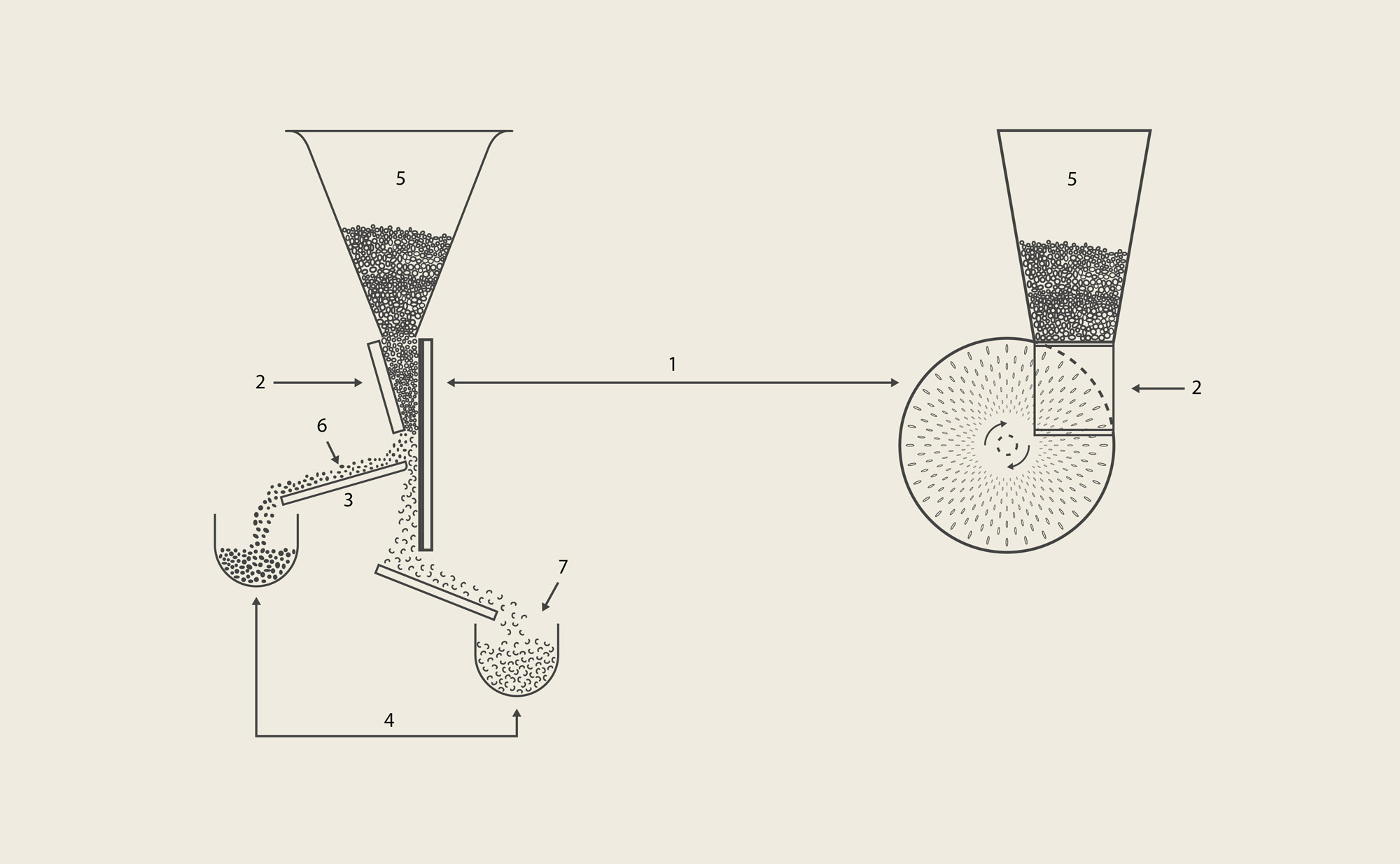

Diagram of a disc pulper, left: side view, right: end view. 1: rotating disc, 2: pulping bar, 3: separating plate, 4: receiving buckets, 5: cherries, 6: beans, 7 pulp.

Diagram of a disc pulper, left: side view, right: end view. 1: rotating disc, 2: pulping bar, 3: separating plate, 4: receiving buckets, 5: cherries, 6: beans, 7 pulp.

The disc pulper was introduced in Ceylon shortly before the huge outbreak of leaf rust that permanently destroyed the nation’s arabica coffee production, in just one generation. The disc pulper was an important innovation because it was lightweight and could be easily transported to remote areas. Rather than abrading the coffee pulp with a horizontal rolling pin,