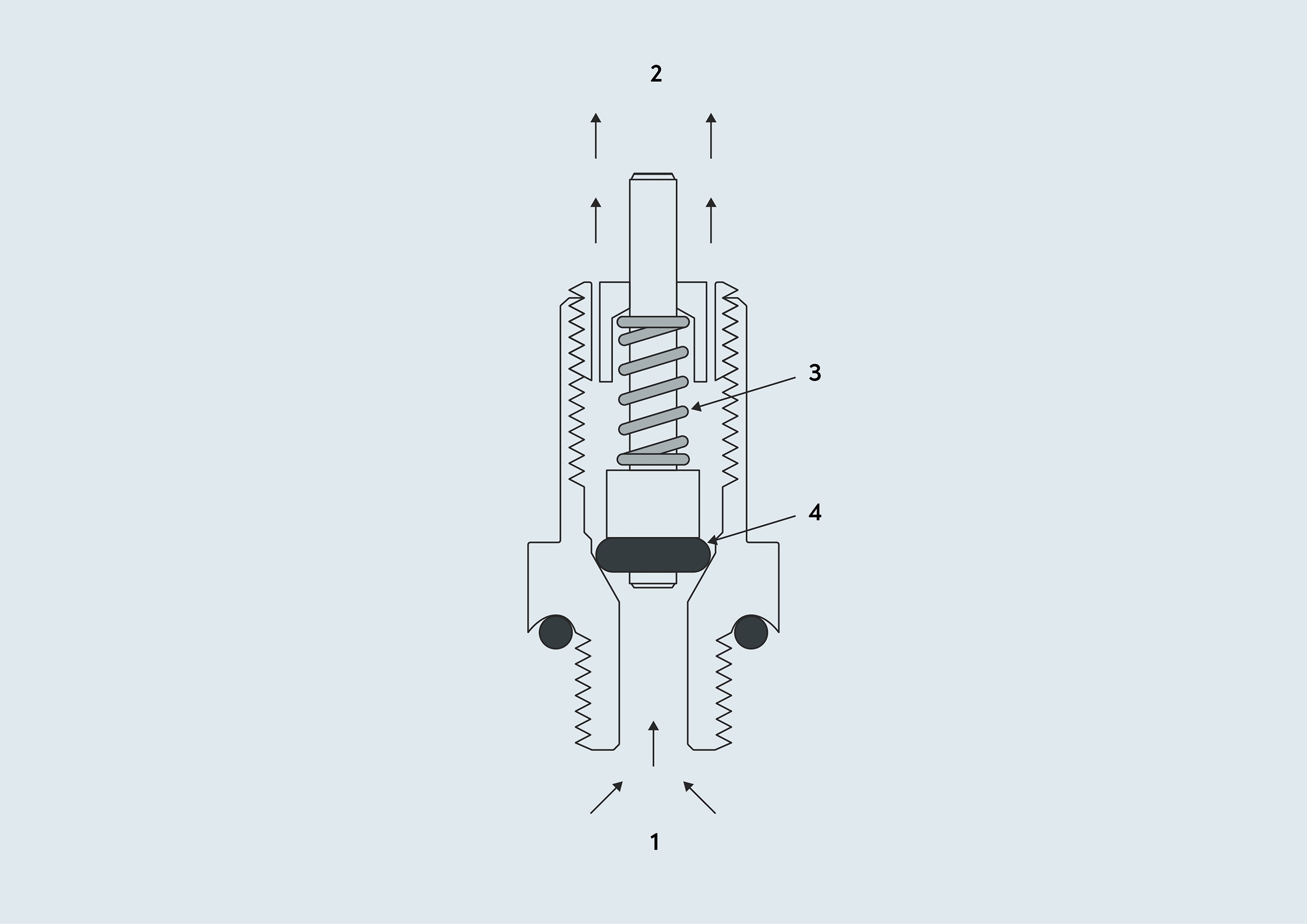

This diagram shows you a cross sectional view of a typical espresso machine safety valve. The spring pushed the seal closed until the pressure excess ~1.6 bars.

This diagram shows you a cross sectional view of a typical espresso machine safety valve. The spring pushed the seal closed until the pressure excess ~1.6 bars.

Espresso machine boilers are designed to function at a setting of 1 bar to 1.3 bars of pressure. However, the steam temperature is well above the normal boiling point of water, which at sea level is 100°C (212°F). The boilers are usually constructed with walls less than 2 millimetres thick. As such, they are not designed to endure more than around 1.6 bars of pressure. If the pressure in a boiler was not prevented from climbing too high, at around 25 bars of pressure, the weldings on copper and steel boilers are expected to burst. It is essential that baristas make regular checks of their machine’s pressure gauges to ensure the boilers remain at safe operating pressures below 1.3 bars.

To control the temperature of a boiler, machines rely on pressurestats and digital devices such as PIDs. (We’ll teach you more about those in Chapter 2.) If these devices were to fail for any reason, electric current would continue to be fed into the tubular elements inside the boiler and the pressure would begin to increase. That’s why it is so important that boilers are fitted with safety valves.

Most safety valves designed for coffee machines will begin to release excess pressure if the boiler pressure exceeds 1.6 bars. On certain types of valves, the threshold setting for when they begin to release pressure can be adjusted — but it is essential that untrained persons leave them well alone. You may notice a tamper wire soldered onto your overpressure valve. This is added to the component to give you a guarantee that the valve pressure has not been adjusted in any way after it was fitted. If you notice the gauge on your machine is above 1.5 bars and/or steam is venting out the top of the boiler, the first thing you should do is switch off the power to the machine.