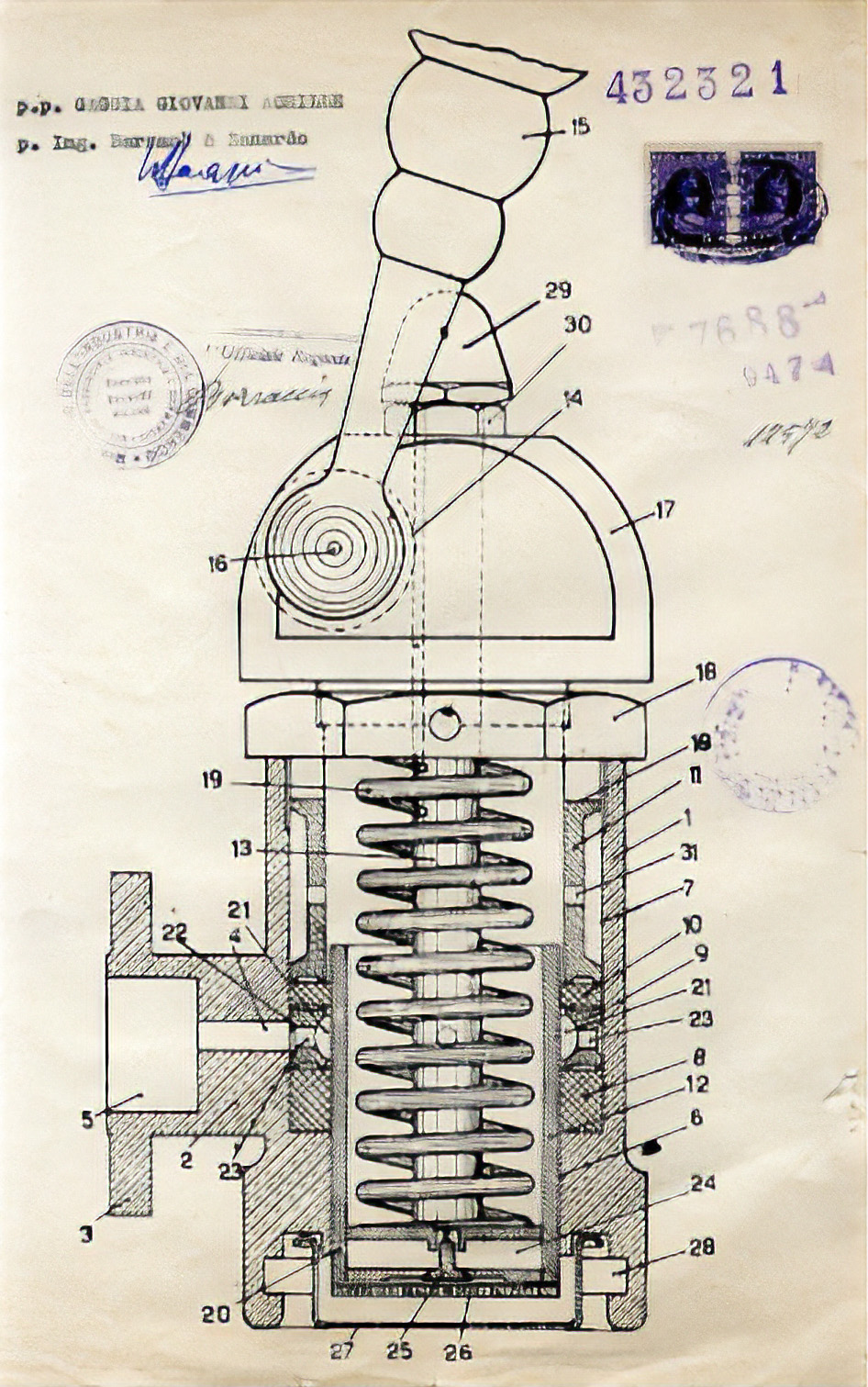

An illustration of the first ever spring lever group head from Giovanni Achille Gaggia’s 1947 machine patent.

An illustration of the first ever spring lever group head from Giovanni Achille Gaggia’s 1947 machine patent.

Lever groups are simple contraptions. They continue to be produced commercially and not that much has changed in the way they are constructed since the first machines appeared in the late 1940s. They consist of a strong brass casing bolted to the boiler of a machine (label 3 in Giovanni Achille Gaggia’s patent illustration above). Inside the casing, a brass sleeve (12) with rubber O-rings at each end (8 and 10) is designed to stop water from escaping. The sleeve (12) has four small perforations to allow water to pass from the boiler (or heat exchanger on more modern systems) into the cylindrical sleeve. A brass plunger (i.e., piston, label 24) slides up and down inside the sleeve.

After the end of World War II, Gaggia was able to recommence production of the Lampo group heads that he had been making based on Cremonese’s design, but he was on the verge of a landmark achievement. Like most of the steps towards the evolution of modern espresso since the beginning of the nineteenth century, it appears to be a minor change to an already existing concept — but what a difference it made. Rosetta Scorza’s screw piston patent, which she had sold to Gaggia before the war, gave him control of the piston concept. But the screw system designed to press down the plunger wasn’t satisfactory in Gaggia’s eyes, and so he redesigned the mechanism. He added a heavy lever to the top of the piston. The lever was to be used to pull the piston upwards, to allow water to enter the group from outside the sleeve.

The major innovation that created a lasting legacy was the innovation Gaggia introduced to push the piston downwards. He fitted a heavy spring, approximately 50 millimetres in diameter and 150 millimetres long, around the outside of the piston. The spring compressed when the lever was pulled downwards. This lever action allowed water to enter the centre of the group and move downwards towards the coffee bed. When the barista released the lever, the water was forced through the coffee bed under extremely high pressure.

In this animation we show you how Gaggia’s lever machine worked.