Over the past couple of decades, the way we heat water in our homes has changed. For example, heat-pump technology has been added to traditional electric storage heaters to recapture energy lost from the storage tank. In addition to innovations such as geothermal heating and the use of evacuated glass tubes for capturing solar energy, many homes have begun to use flow heaters (also known as flow-through heaters) rather than storing hot water in a tank. Flow heaters, which heat only the amount of water needed, can reduce energy consumption by approximately 40%.

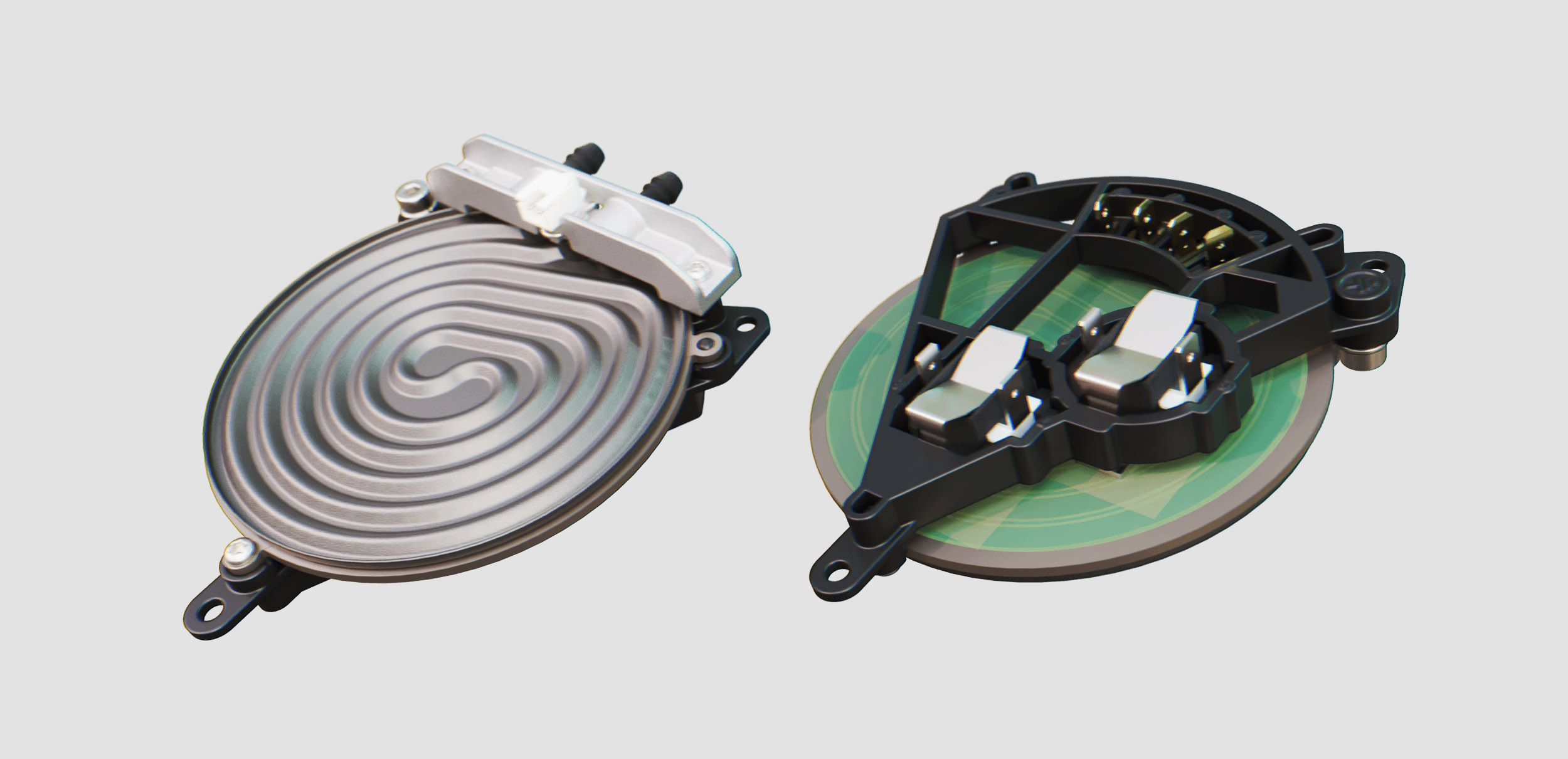

This video from Dutch company, Ferro Teckniek shows the inner workings of their flow heaters.

Flow heaters work by guiding water across the surface of a heating element that is encased within a maze-like stainless steel channel. Because every millilitre of water travels across almost the entire surface of the heating element, this technology results in substantially improved energy efficiency. The maze typically holds around 10 mL of water. This low volume-to-surface ratio allows manufacturers to encode temperature profiling capabilities into their machines.

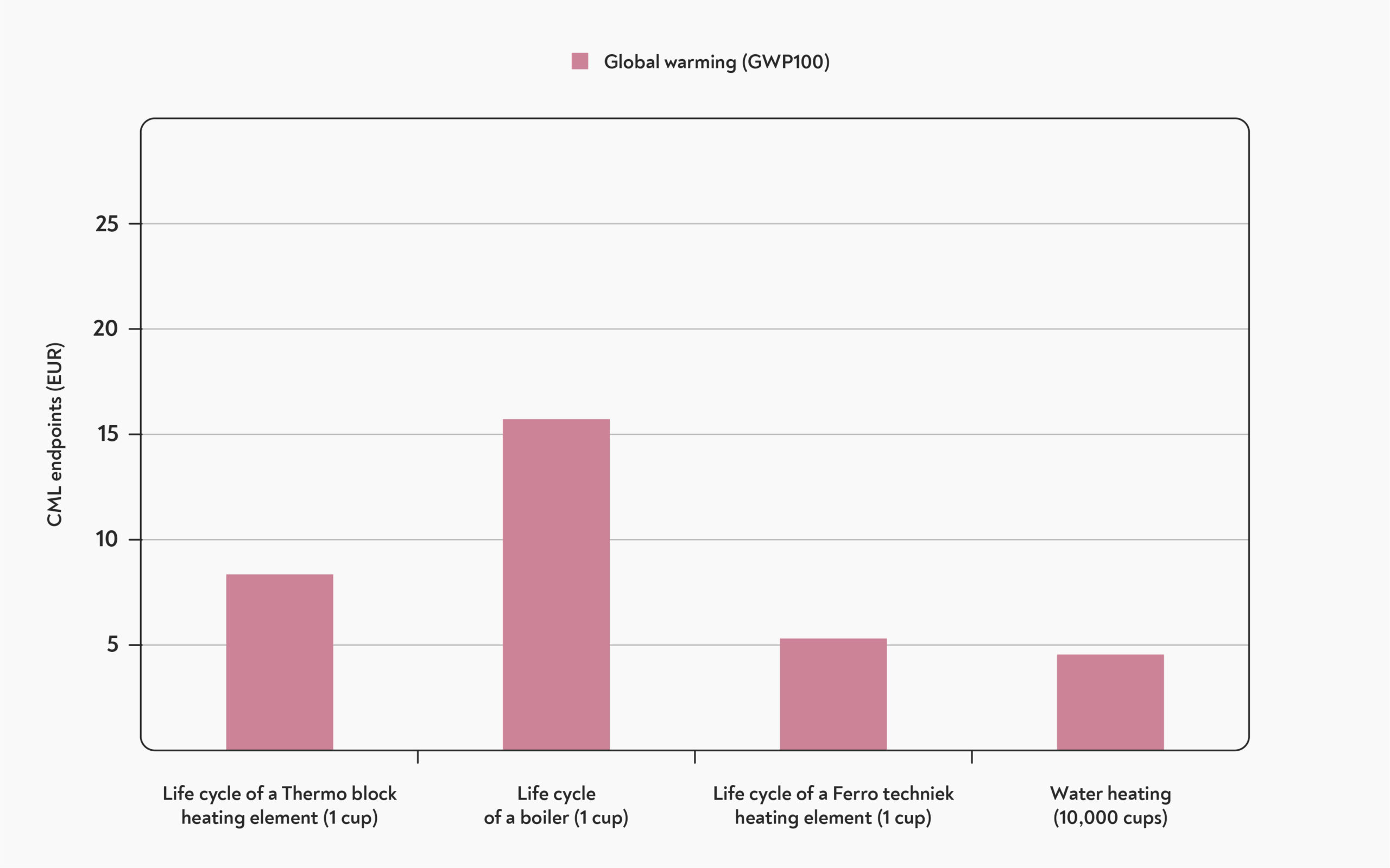

The results of a life-cycle assessment comparing a Ferro Techniek flow heater, an ordinary boiler, and a thermal block heating system. Whilst this study shows that thermal blocks (the system usually used on small appliances such as capsule machines) can halve the global warming potential of boiling water compared with using a conventional boiler, a flow heater reduces GHG emissions by a factor of two-thirds.

The results of a life-cycle assessment comparing a Ferro Techniek flow heater, an ordinary boiler, and a thermal block heating system. Whilst this study shows that thermal blocks (the system usually used on small appliances such as capsule machines) can halve the global warming potential of boiling water compared with using a conventional boiler, a flow heater reduces GHG emissions by a factor of two-thirds.

As energy demands increase and global warming advances, it is clear that either a change in coffee makers design or a change in how we produce energy is required. Ever since Elard Römershausen, a German doctor, first designed his brewer in 1818, a seemingly inescapable design principle has made espresso machines very energy intensive.

Römer’s coffee maker, from 1818

Römer’s coffee maker, from 1818

Initially, the need for a boiler came from the false notion that to achieve the best coffee flavour,